The wooden board that riders stand on is more commonly referred to as skateboard decks. The rider then attaches wheels and bearings to their skateboard decks to start riding on it. A skateboard is a surfboard-shaped wooden board with four sets of wheels attached beneath it. The game board allows only one individual at a time, and movement control is achieved with the assistance of feet. It is a good choice for use as a means of transportation within a fair distance and during certain stunts. All types of skateboards are designed with comparable characteristics, regardless of usage. vdcasino

You’ll need to understand the skateboard’s parts, which are divided into three categories: the actual board, the deck, the wheels, and the truck. Its size varies but is generally around 81.3cm long and 20.3cm broad. The thickness of the board is usually less than 1.3cm unless otherwise specified. The deck comprises two distinct components: a nose and a tail connected in the middle.

How to Make Skateboard Decks

Decks for skateboards were originally one flat and solid sheet of wood, but now they are a type of engineered wood product molded into shape and held together with glue. If we’re looking for a wood product that has good strength in both directions, we should alternately rotate the veneer layers. deneme bonusu

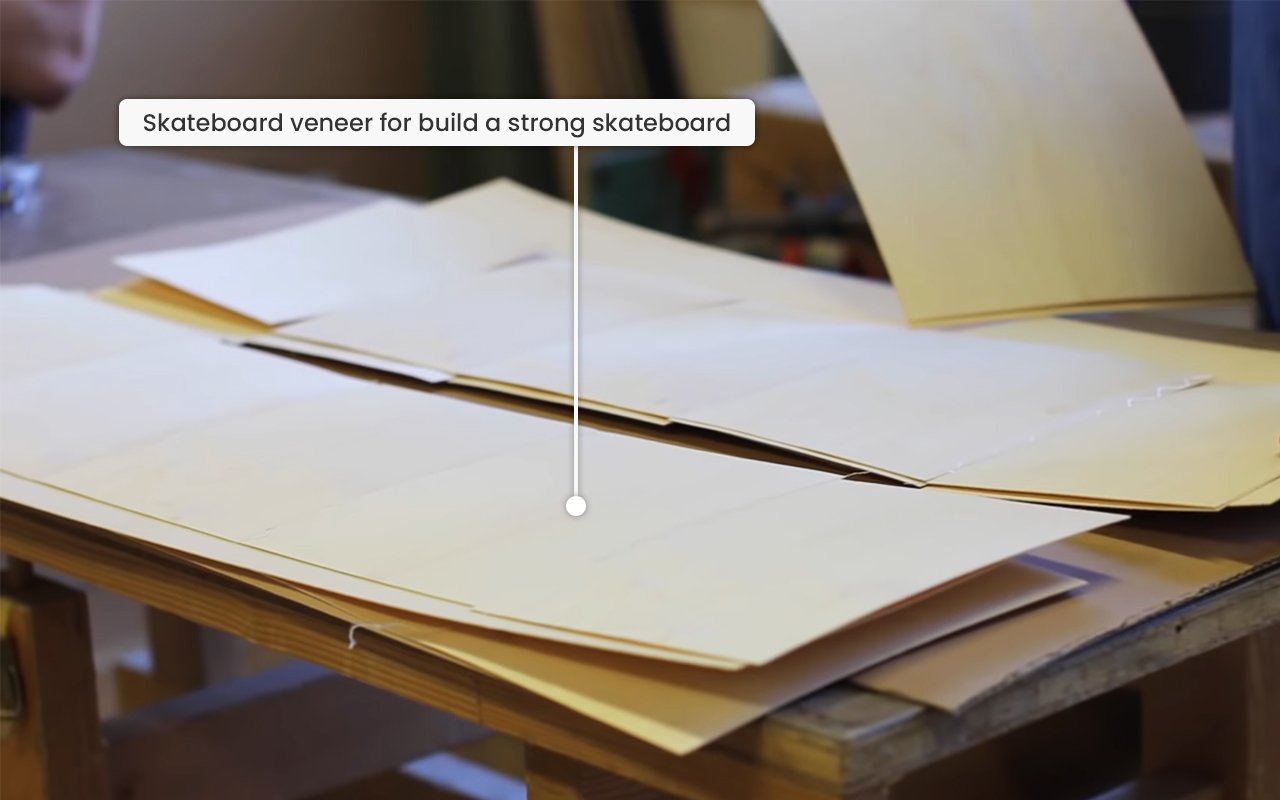

Skateboard Veneer

The three layers of a skateboard’s veneer are unsanded or sanded core ply, the face ply, and the cross band plays. These plies are usually unsanded. The layers’ shape and arrangement significantly impact the board’s weight, strength, and roughness. The skateboard’s bottom veneer might be composed of different types of wood or a blend of wood kinds, producing a geometric design for the sake of beauty.

The plies may be organized in a variety of ways. betvole giriş

- Face

- Core layer

- Crossband

- Core layer

- Crossband

- Core layer

Veneers are generally available in the order of thickness above, although this depends on your outcome.

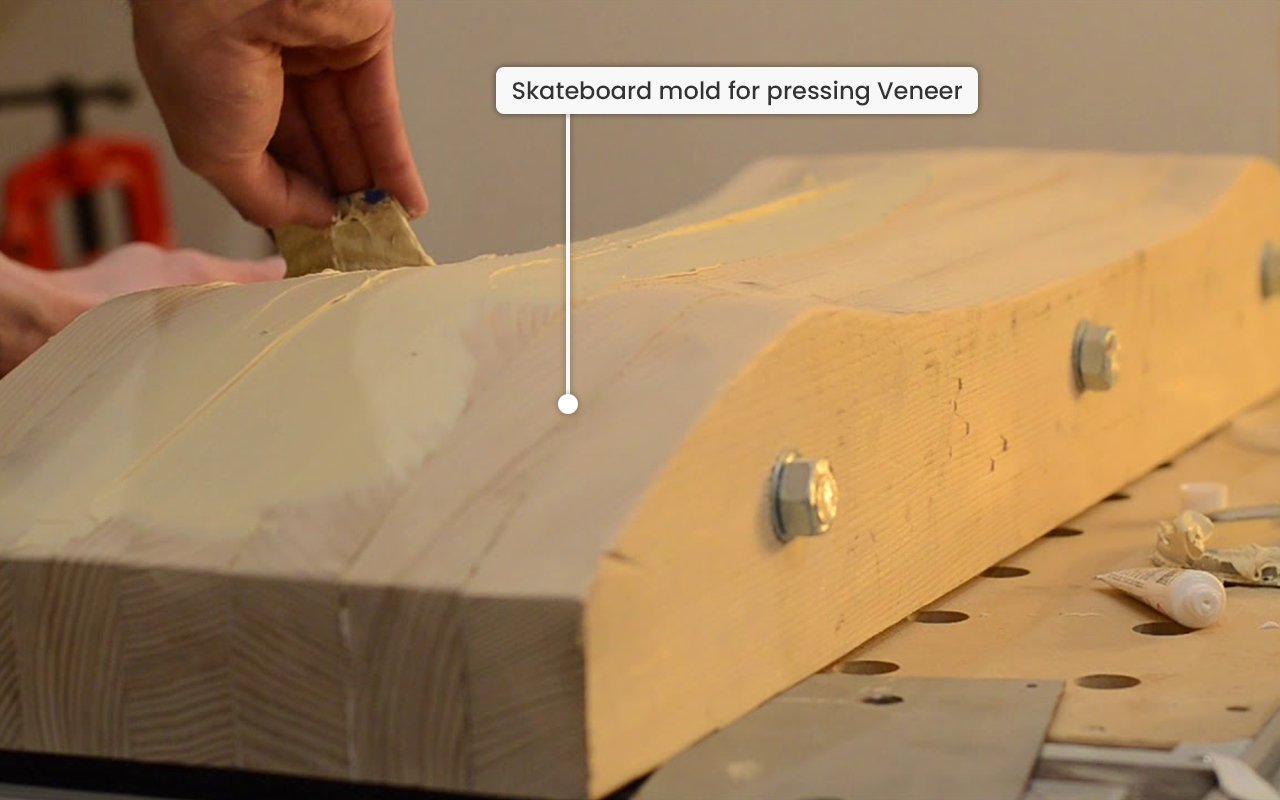

Skateboard Molds

After that, you’ll need to make a mold out of the veneer. The mold plays a role in producing the desired form. There are many types of mold, including wood, foam, concrete, and aluminum. You can also create molds from any scrap wood or plywood that you have in your workshop. To create wood molds, start by cutting the scrap wood to an exact size.

It’s essential to choose the correct mold. The mold determines the kind of press to be utilized, the number of Skateboard Decks you want to construct, the required area, and your present financial situation.

There are many things to consider when choosing the proper mold. The number of Skateboard Decks you wish to produce, the type of press you’ll use, how many decks you want on each side, how much space you have, and your financial constraints will influence this choice.

Skateboard Glue

You can also use high-quality glue for woodwork or glues designed explicitly for skateboards. We can use wood glue, epoxy, or special glue for skateboard decks. You may use a paint roller to spread the glue over the entire surface you want to protect. On the other hand, a paint roller will have enough reach to access all aspects and corners. Use a roller with a little nap measuring less than 4 inches. The amount of glue required on a specific surface might vary depending on the type of glue being utilized. If you have a dry roller, use three ounces on each veneer; if the roller is glue-wet, use two ounces on each veneer. To avoid unsightly glue stains, ensure that the coat is equally distributed and that none of the spots have dried glue. Skateboards are constructed of thin layers of wood that are glued together and formed into a plank.

If you’re using an actual skateboard glue like Multibond Sk8 or PC-2365, which has the correct amount of material, you can remove your decks in about two hours.

When building a skateboard, one of the most significant problems you’ll encounter is delamination resulting from insufficient glue. As a result, it’s critical to complete the procedure rapidly and ensure that the adhesive covering the veneer is adequate.

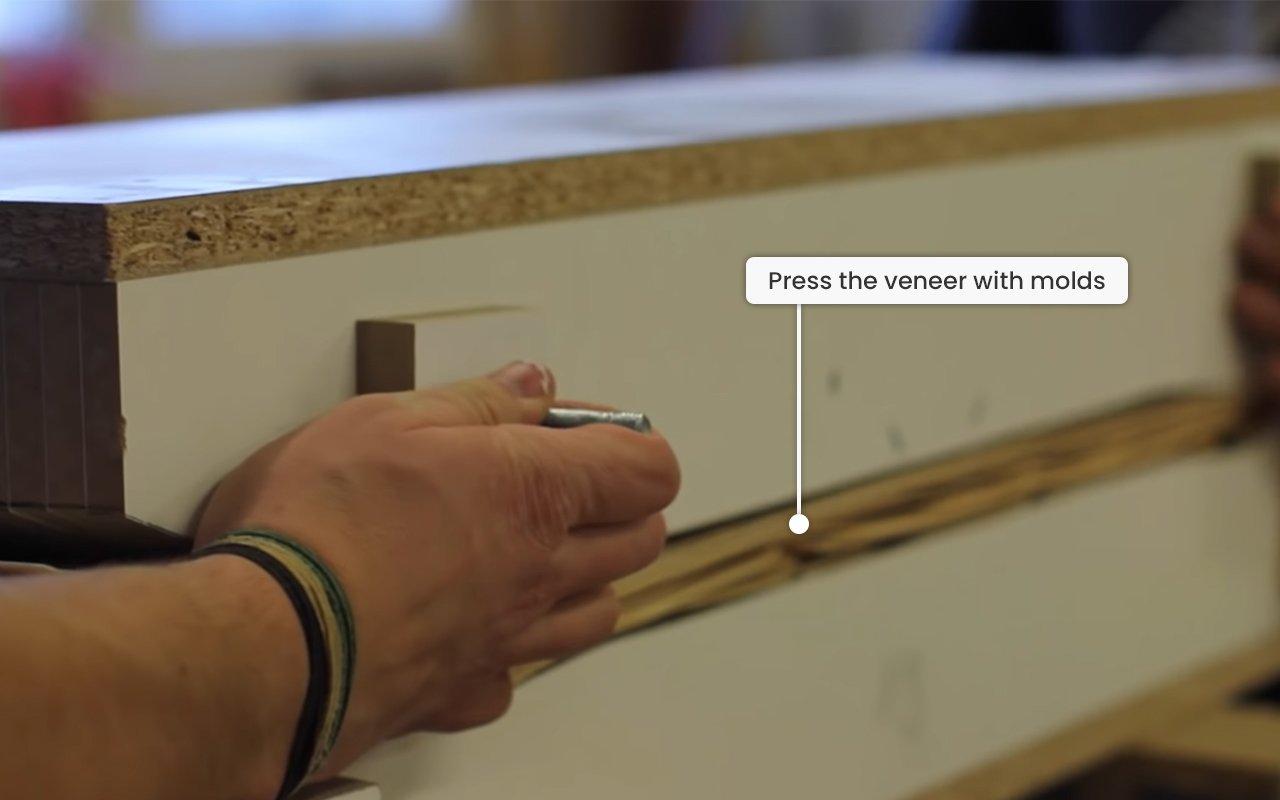

Skateboard Press

The mold size is all that matters regarding the machine press’s range. Cool pressing the veneer might be crucial regardless of the mold used, which may be completed at room temperature. Pressure should be set at 25 tons or 175 psi, although numerous elements should be considered when determining the appropriate pressure. The hydraulic press is a cold press that uses normal pressure without additional heat.

There are adhesives on the market that can endure for 15–20 minutes if properly distributed. If the glue you’re using is intended for skateboards, such as PC-2365, with the correct amount and Multi-band, you should be able to remove the deck in 1–2 hours.

Suppose the tonnage of your glue is less than anticipated. For example, if you use a 5-ton press, you’ll need to leave the veneer in the skateboard press for an extended time. For at least 24 hours.

Allow another 24 hours for the board to cure after removing it from the mold before doing additional work. Cleaning out the wood and glue will help them dry thoroughly.

Drilling the Holes

You’ll need a drill press to make holes in the deck. A standard drill is suggested, but you must ensure that all holes are vertically oriented on the Skateboard Decks surface.

To discover each hole, you’ll need to utilize an old deck as a guide or take precise measurements to establish the deck’s center and wheelbase, then go on.

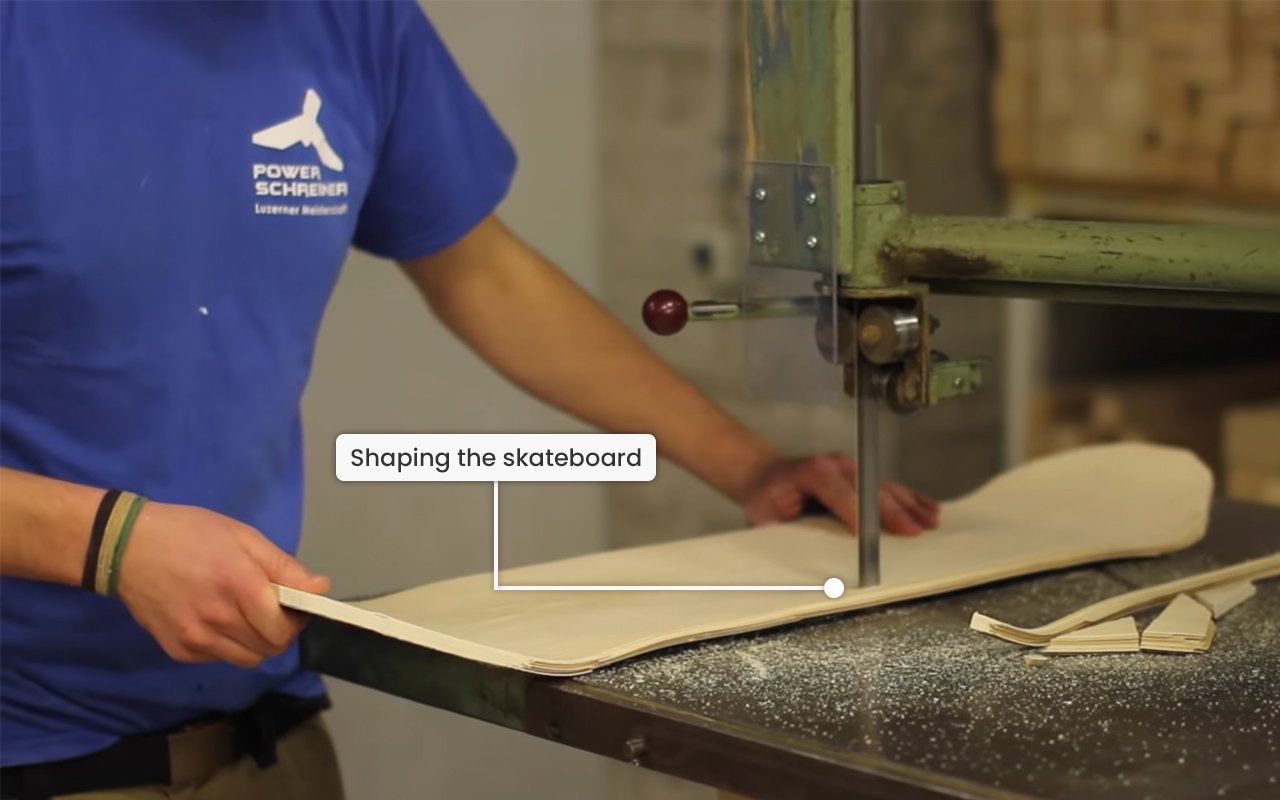

Shaping the Skateboard

To obtain the proper form, you’ll need a deck that acts as a template. Tracing out the deck that will be your template on the blank you wish to utilize is a good idea; now, use a jig or band saw to cut it out following the form of your template.

Rounding and Sanding the Skateboard

The most common approach to removing rounded corners on your deck is by sanding or routing them. You may accomplish this by using a remote or palm router since operating it is less complicated, and you can quickly move around small areas. The size of the radius is determined by personal preference. Sand the entire board on both sides and all around the edges until it’s as smooth as can be.

Once your deck’s edges have been properly smoothed and shaped, the next stage is to sand the deck’s surface. You may accomplish this with 80 to 100 grit sandpaper, which you should go up to 200 to 210 grit sandpaper. You’ve completed the first step, which is to make a super-smooth deck. After you finish sanding, add a stain, paint on graphics, or use a wood burner to make the board into your custom design.

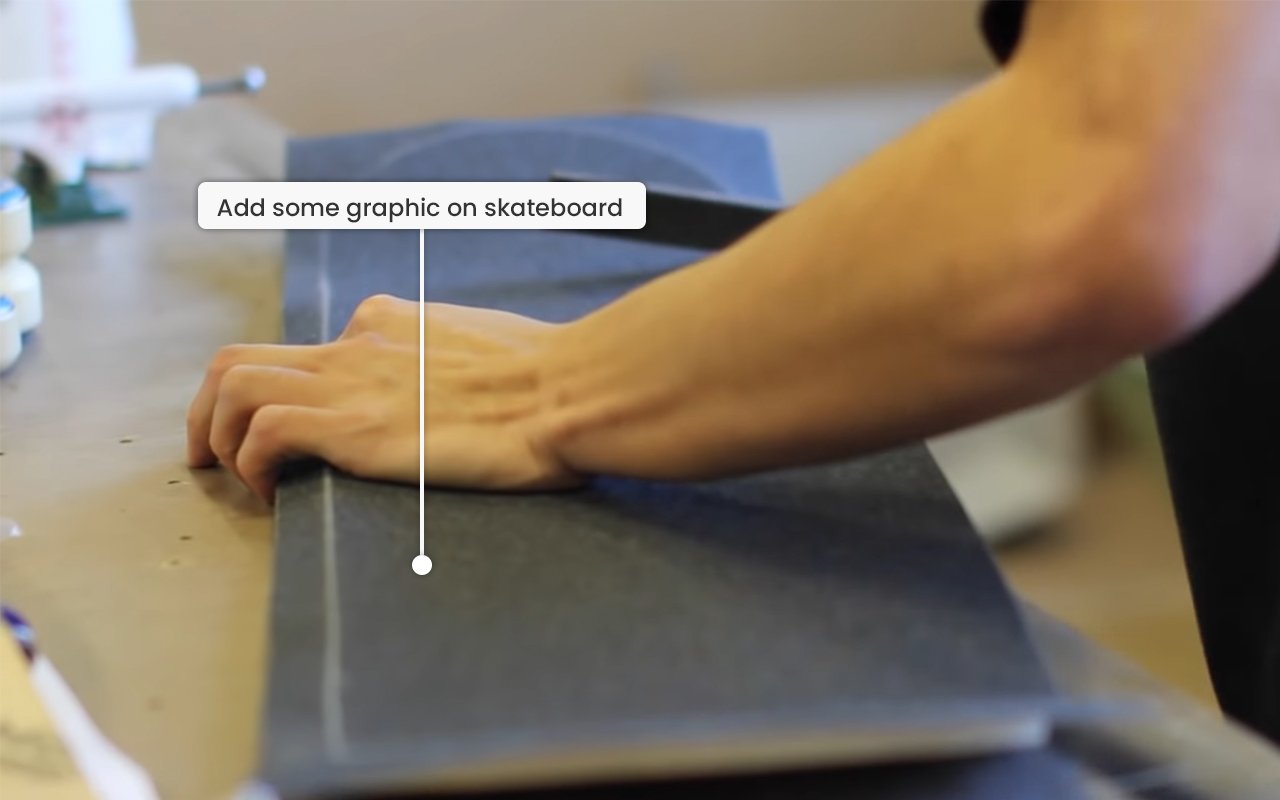

Graphics

When you’ve finished sealing the surface, it’s time to move on to the “Graphic Phase.” Spray paint, stencil, screen print, or freehand are all viable methods; it’s up to you whether you want a more artistic look or a more industrial design. All you need is to paint with the same or similar color as your final finish and sealer. If you used a solvent-based sealer, you’d need to use a solvent-based paint. If the sealer is water-based, you’ll need to apply water-based paint. The graphic of the board turned out great, and the board shape is fantastic. Both graphics were produced with high-quality graphics in mind.

Sealing the Skateboard

Remove the sawdust from the deck surface with a tack cloth once your deck is smooth enough. We may use cheesecloth with a wax coating as your tack cloth. After you’ve cleaned and resealed your deck, the next step is to finish it off with a smooth, debris-free surface.

Final Coat

The board should be air-dried using a tack cloth, and the board’s deck cleaned after completing the design. You may seal the deck with a clear or colored lacquer, determined by your product.

FAQ

Q1. What kind of wood is used in skateboard decks?

The majority of the deck, about 75 percent, is constructed of maple wood from North America. The wood is highly durable and sturdy. Conventional skateboards are made of maple wood strips that are fastened together with epoxy or adhesive glue.

Q2. How much does a skateboard deck cost to produce?

The most cost-effective skateboards generally sell for around $160-$170. The trucks and deck are the skateboard’s most expensive components. If you want a more budget-friendly option, prepare to invest at least $64 if you intend on building the gadget from the bottom up. Make sure you pick the deck for your skateboard wisely so that it will perform at its best.

Q3. How long should a skateboard last?

If you skate on a regular basis, your deck will need to be replaced at some point. Depending on the quality and brand of deck you choose, you may need to refresh IT within 2-3 months.

It’s not difficult to construct a skateboard if you follow the appropriate advice and use the right supplies and equipment for the job. If you follow the guidelines, the process will be enjoyable. Once your board is complete, you can begin the learning process, but ensure you have all your required gear.

Q4. What glue is used to make skateboards?

Franklin Multibond Sk8 Glue is a type of wood glue popular among manufacturers since it has better adhesion, waterproofing, and endurance over time. Even if you leave your board in the rain or remove it from a steep drop, Multibond Sk8 Glue keeps it intact.

Q5. What skateboard material is best?

Maple wood is a great skateboard material because it is flexible yet strong, allowing it to be readily molded without sacrificing strength. It’s still the most popular skateboard deck material. Most inexpensive plywood is produced from softwoods, like pine, and the layers are formed by bonding smaller pieces of wood together with epoxy resin.

Q6. Can you make your skateboard deck?

Many believe that making a skateboard is not as difficult, if not as challenging. Making a skateboard deck, or wooden board, requires only a rudimentary understanding of carpentry, a jigsaw, and a skateboard mold, but they may also be manufactured at home with some perseverance.

Q7. Why is aluminum suitable for skateboard trucks?

The majority of skateboard trucks are made of aluminum. Lightweight, biodegradable, and capable of being ground, aluminum is all true. The aluminum truck has a better riding experience than the steel model. On the other hand, steel is heavier, more robust, and longer-lasting, but it will add weight to your deck.

Blog Comments

Blitzart 700W Electric Skateboard Longboard Review

September 5, 2022 at 12:40 pm

[…] electric longboards and skateboards are more expensive than regular skateboard decks, you want to make sure your investment is protected. Avoid purchasing an inexpensive, lower-quality […]